Tool manufacturing

From a 3D model to the finished product – it all comes from the same place

Our strengths in tool manufacturing

We work closely with our customers

Whether it’s a prototype, a small series tool or a mass production tool - from component development all the way up to the start of production, we work closely with our customers.

This is the key to our high levels of proficiency!

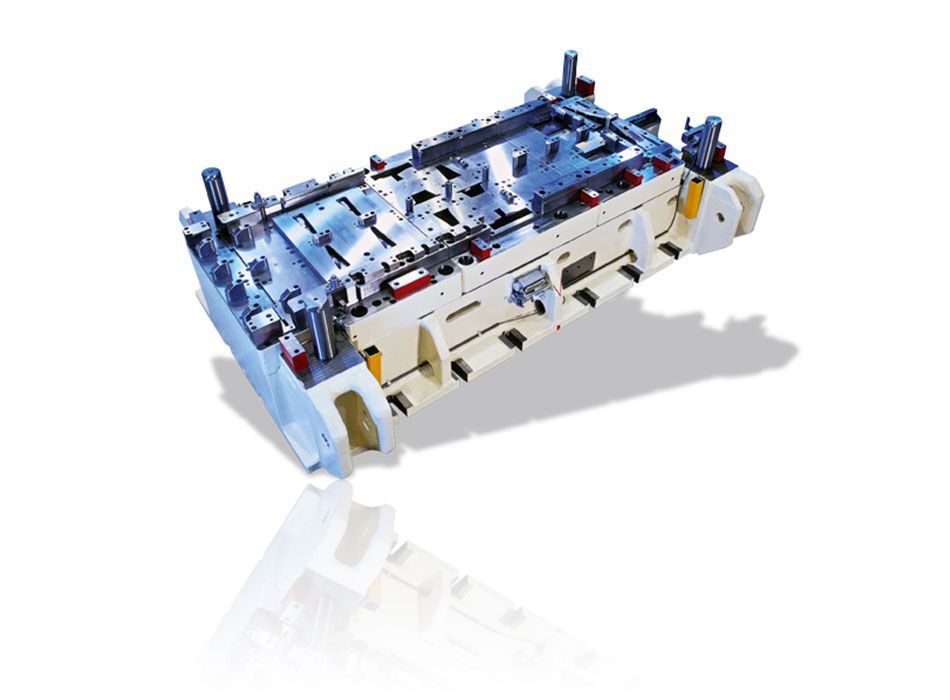

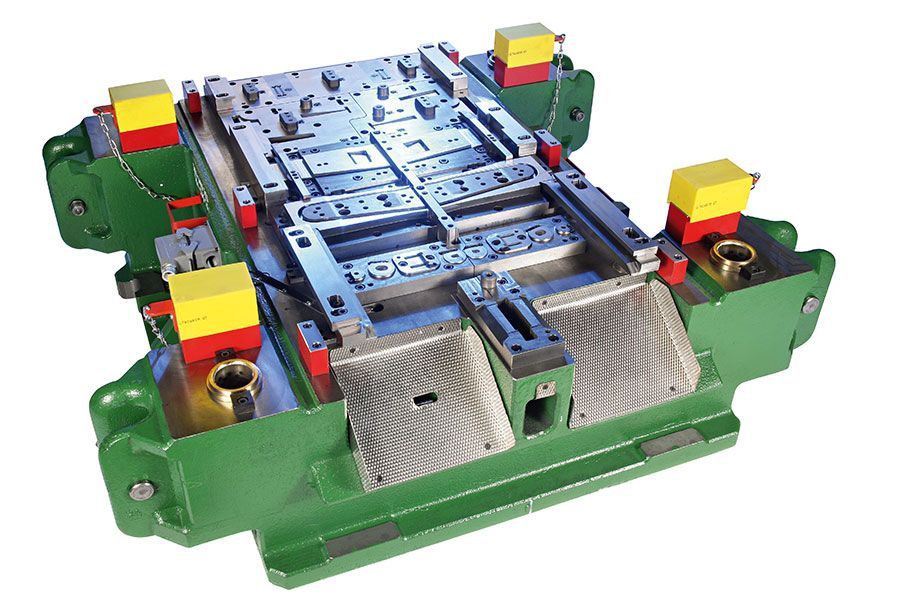

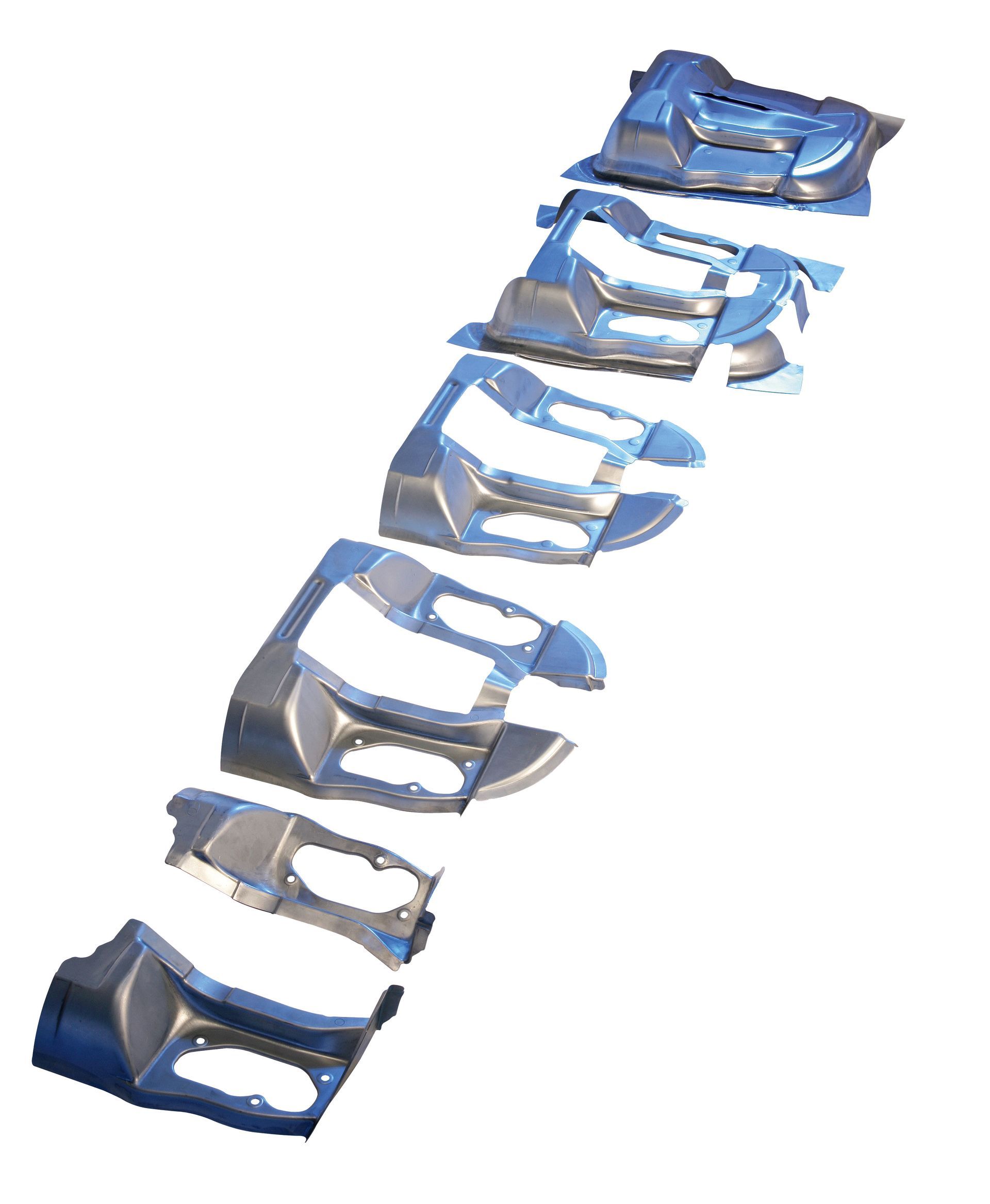

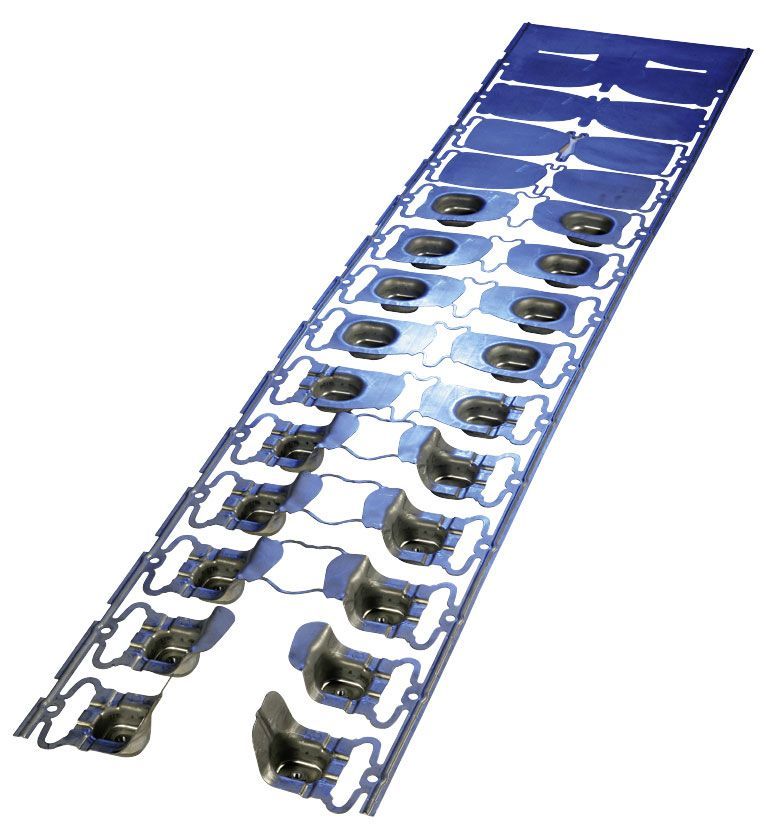

Progressive tools are ideal for the manufacturing of small to medium-sized sheet metal parts, which can be joined in the middle and/or on the outside with a crosspiece. For the production of medium-sized to large sheet metal parts, which cannot be manufactured using progressive tools due to their shape, size or weight, transfer tools are the ideal solution. A vast variety of materials (from soft to ultra-high strength steel as well as all kinds of aluminium alloys) of thicknesses between 0.5 to 6 mm can be converted.

Perfectly suited to the cost-effective production

Both kinds of tools are perfectly suited to the cost-effective production of medium and high quantities of complex sheet metal parts, with the highest quality control and tolerance requirements.

However, if the requirement is the efficient production of a small to medium quantity of sheet metal parts, the use of handheld tools as individual or multi-stage tools is advantageous.

The right tool for every requirement

WEFOMA hasn’t just made a name for itself as a toolmaker. Upon request, WEFOMA can also manufacture sheet metal parts as prototypes, samples and pilot productions with its usual precision and high quality.